| Item | Index | |

|---|---|---|

| Appearance | Colorless, odorless, tasteless and lustrous transparent solid. | |

| Purity %≥ | 98 | |

| Melting point ℃ | 212 °C | |

| Resins | Polymer Matrix Structure | Physical Form Appearance | Surface nArea m2/g | Average Pore Diameter | Adsorption Capacity | Moisture Content | Particle Size mm | Shipping Weight g/L |

|---|---|---|---|---|---|---|---|---|

| AB-8 | Macroporous Ploy-styrene with DVB | Opaque White Spherical Beads | 450-550 | 103 nm | - | 60-70% | 0.3-1.2 | 650-700 |

| D101 | Macroporous Ploy-styrene with DVB | Opaque White Spherical Beads | 600-700 | 10 nm | - | 53-63% | 0.3-1.2 | 670-690 |

| D152 | Macroporous Pype Poly-acrylic with DVB | Opaque White Spherical Beads | - | Na/H | 1.4 meq.ml | 60-70% | 0.3-1.2 | 680-700 |

| H103 | Post Crosslink styrene with DVB | Dark brown to black Spherical | 1000-1100 | - | 0.5-1.0TOC/g100mg/ml | 50-60% | 0.3-1.2 | 670-690 |

| Packing | in 25kg bags |

|---|---|

| Storage | 20°C,2 years |

| Shipping | Room temperature in China;may vary elsewhere |

Tel: 0086 25 52397805

Email: sales2@nj-finechem.com

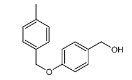

| Common Names | Wang resin | ||

|---|---|---|---|

| Structure |  |

||

| CAS No. | 201058-08-4 | Boiling Point (℃) | 386.2ºC at 760 mmHg |

| Molecular Weight | 228.286 | Melting Point (℃) | N/A |

| Appearance | Off-white to beige beads | Vapor Specific Gravity | - |

| HS Code | 3909400000 | Flash Point (℃) | 175.2ºC |

| Solubility | - | Autoignition Temperature (℃) | - |

| Safety Phrases | 26-36/37/39-24/25 | ||

|---|---|---|---|

| RIDADR | 2211 | ||

| WGK Germany | 3 | ||

| Packaging Group | III | ||

| Hazard Class | - | ||

| SYMPTOMS | PREVENTION | FIRST AID | |

| Inhalation | poisonous | wear a mask | fresh air,keep breath comfortable |

| Skin | skin burn | wear protective clothing | Remove all soiled clothing and wash your skin with water. |

| Eyes | eye injury | wear goggles | Rinse slowly and gently with water for a few minutes |

| Ingestion | poisonous | Do not eat, drink or smoke while using this product | Call a POISON CENTRE or doctor |

What is Macroporous Adsorptive Resins?

Macroporous adsorption resin is a kind of polymer adsorption resin without exchange group and macroporous structure. It has good macroporous network structure and large specific surface area. It can selectively adsorb organic matter in aqueous solution through physical adsorption. It is a new type of organic polymer adsorbent developed in the 1960s. It has been widely used in environmental protection, food, medicine and other fields.

Macroporous adsorption resin is generally white spherical particles with particle size of 20-60 mesh. The macrospheres of macroporous adsorption resin are composed of many micro spheres with holes in each other.

Macroporous adsorption resin was polymerized with styrene, divinylbenzene, etc. in 0.5% gelatin solution and a certain proportion of porogen. Styrene was used as monomer, divinylbenzene as crosslinking agent, toluene and xylene as porogens. They were crosslinked and polymerized to form the porous framework structure of macroporous adsorption resin.

How is Macroporous Adsorptive Resins stored and distributed?

Handling, loading and unloading operations should be gentle, stable and regular stacking, do not fall

violently. Spillage may lead to slippery ground, so be careful to prevent slipping.

Storage The storage temperature of this material should not be higher than 90℃, and the maximum use

temperature is 180℃.

Store at 0℃ or above in the wet state. Please keep the package sealed and intact in the storage

state to prevent water loss; in case of drying and water loss, the dry resin should be soaked in

ethanol for about 2 hours and washed with water before re-packaging or using.

Do not freeze the ball in winter. If freezing is found, please melt it slowly at room

temperature.

During transportation or storage, do not mix and stack with odor, toxic substances and strong

oxidizers.

What is Macroporous Adsorptive Resins used for?

Large pore adsorbent resin adsorption technology was firstly used in the fields of wastewater treatment, pharmaceutical industry, chemical industry, analytical chemistry, clinical testing and treatment, etc. In recent years, it has been widely used in our country for the extraction, separation and purification of the active ingredients of traditional Chinese herbal medicine. Compared with the traditional process of Chinese medicine preparation, the extract obtained by applying the technology of large-pore adsorption resin is small in size, does not absorb moisture, and is easy to be made into various dosage forms with beautiful appearance, especially suitable for granules, capsules and tablets, which has changed the phenomenon of coarseness, blackness and bigness of the traditional Chinese medicine preparation, which is conducive to the upgrading of the dosage form of the traditional Chinese medicine preparation and promotes the modernization of the development of the research of Chinese medicine, and is also a key factor in the modernization of Chinese medicine, which has been jointly issued by the State Administration of Traditional Chinese Medicine. 2002~2010 "Pharmaceutical Science and Technology Policy" clearly puts forward: research and development of dynamic countercurrent extraction of Chinese medicine, supercritical extraction, infiltration of Chinese medicine tablets, macroporous resin separation and other technologies.