Polyacrylic Acid Sodium Salt

NANJING FINECHEM HOLDING CO., LTD

General Information

Chemical & Physical Properties

Safety Information

Synthetic Route

| Common Names |

Polyacrylic acid|Propenoic acid polymer |

| Structure |

|

| CAS No. |

9003-04-7 |

Boiling Point (℃) |

116ºC |

| Molecular Weight |

2000(Average) |

Melting Point (℃) |

106ºC |

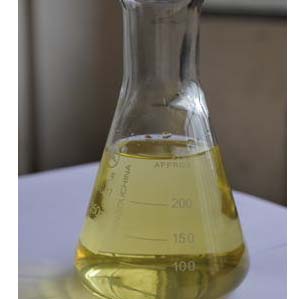

| Appearance |

Colorless to yellow liquid |

Vapor Specific Gravity |

N/A |

| HS Code |

3906909090 |

Flash Point (℃) |

61.6ºC |

| Solubility |

Soluble in water. |

Autoignition Temperature (℃) |

N/A |

| Safety Phrases |

S24/25 |

| RIDADR |

UN 3265 8/PG 3 |

| WGK Germany |

3 |

| Packaging Group |

N/A |

| Hazard Class |

N/A |

|

SYMPTOMS |

PREVENTION |

FIRST AID |

| Inhalation |

Cough. Sore throat. |

Use local exhaust or breathing protection. |

Fresh air, rest. |

| Skin |

Redness. Burning sensation. Itching. |

Protective gloves. |

Remove contaminated clothes. Rinse and then wash skin with water and soap. |

| Eyes |

Redness. Pain. |

Wear safety goggles. |

First rinse with plenty of water for several minutes (remove contact lenses if easily

possible), then refer for medical attention. |

| Ingestion |

Abdominal pain. Nausea. Vomiting. |

Do not eat, drink, or smoke during work. Wash hands before eating. |

Rinse mouth. Induce vomiting (ONLY IN CONSCIOUS PERSONS!). Refer for medical attention. |

The deionized water and 34kg chain transfer agent isopropanol were added to the reactor in turn and

heated to 80~82 °C. Add 14 kg of ammonium persulfate and 170 kg of monomer acrylic acid in aqueous

solution (deionized water) dropwise. After dripping, the reaction is 3h. Cool to 40 °C, add 30% NaOH

aqueous solution, neutralize to pH 8.0~9.0 to evaporate isopropanol and water to obtain liquid products.

Spray drying to obtain solid products acrylic acid or acrylate reacted with sodium hydroxide to obtain

sodium acrylate monomer, remove by-generated alcohols, concentrate and adjust pH value, polymerize

ammonium persulfate as a catalyst to obtain sodium acrylate monomer by reaction of acrylic acid and

sodium hydroxide, and then under the catalysis of ammonium persulfate, polymerize into sodium

polyacrylate and add sodium polyacrylate with a relative molecular weight of 1 000~3 000 into the

reactor and prepare a 30% aqueous solution

Frequently Asked Questions

What is Polyacrylic Acid Sodium Salt?

Polyacrylic Acid Sodium Salt is a new type of functional polymer material and an important chemical

product. The solid product is white or light yellow block or powder, and the liquid product is colorless

or light yellow viscous liquid. It is obtained from acrylic acid and its esters through aqueous solution

polymerization. Odorless, soluble in aqueous sodium hydroxide solution, precipitated in aqueous

solutions such as calcium hydroxide and magnesium hydroxide. It is often used as water treatment agent,

brine refining and latex thickening, and can also be used as food thickening and emulsification.

What is Polyacrylic Acid Sodium Salt used for?

Thickener

1. It has the following effects in food:

(1) Strengthen the protein cohesion in raw flour.

(2) Make the starch particles combine with each other, disperse and penetrate into the network structure

of the protein.

(3) Form a dense dough with a smooth and shiny surface.

(4) Form a stable dough colloid to prevent oozing out of soluble starch.

(5) Strong water retention, so that the water is evenly kept in the dough to prevent drying.

(6) Improve the extensibility of dough.

(7) Make the oil components in the raw materials disperse stably into the dough.

2. Interact with protein as an electrolyte, change protein structure, enhance viscoelasticity of food,

and improve tissue.

3. Since it dissolves slowly in water, it can be mixed with granulated sugar, powdered starch syrup,

emulsifier, etc. to increase the dissolution rate.

4. As a clarifying agent (polymer coagulant) for sugar liquid, salt water, beverages, etc.

Other Applications

1. Used as corrosion and scale inhibitor, water quality stabilizer, paint thickener and water retention

agent, flocculant, drilling mud treatment agent, etc.

2. It is used for circulating cold water treatment of copper equipment, and its scale inhibition effect

is good. When the dosage is 100 mg/L, it can form chelate complexes with scale-forming ions in medium

hardness water and flow with the water, and it can prevent the formation of iron oxide scale.

3. Used as fluid loss reducer in low solids drilling industry.

4. Good dispersant. It can be used in combination with other water treatment agents for oilfield water

injection, cooling water, and boiler water treatment.